Process Overview

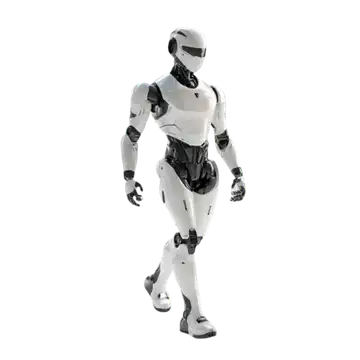

This case study showcases a logistics automation solution that uses VisionNav’s VNPA15 autonomous mobile robot (AMR) to automate the transport and loading/stacking of packaged products in indoor material-handling operations.

Built on robust safety functions, the solution minimizes changes to existing workflows while enabling unattended load/unload tasks, and provides effective monitoring and control of real-time operations.

구성요소

| 로봇 | VisionNav VNPA15 (Autonomous Counterbalanced Truck) Lifting height: 0–4,500 mm Max payload: 800 kg Min. stacking aisle width: 3,200 mm Dimensions (W×D×H): 2,790 × 1,185 × 2,110 mm Vehicle weight: 2,640 kg |

|---|

작업순서

| STEP 1. | Transport/stacking task dispatch |

|---|---|

| STEP 2. | Navigate to the pick location |

| STEP 3. | Pick from a two-level stacked load |

| STEP 4. | Navigate to the truck position and unload |

※ 마로솔 내의 모든 콘텐츠를 무단으로 복사 및 재창작할 경우 부정경쟁방지법 및 저작권법에 위반될 수 있음을 밝힙니다.

추천 도입사례

Smart Palletizing Using the Hyundai Robotics HH050 and Mech-Mind 3D Vision 🦾🤖

Full automation of injection molding line logistics with AMR logistics robots